VAK CONVEYING SYSTEMS LTD

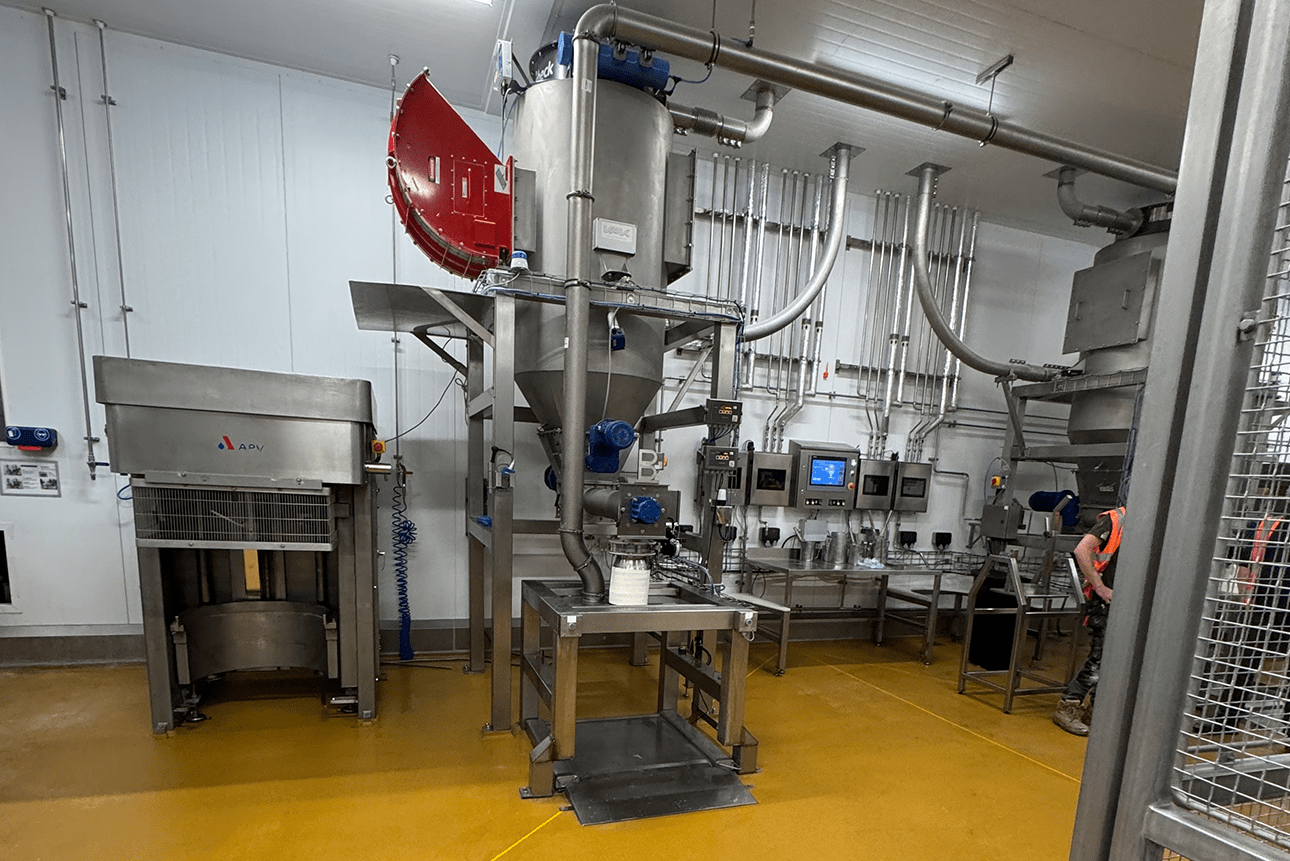

Turnkey Systems

End-to-End Material Handling Solutions—Designed, Built & Delivered by VAK

At VAK Conveying Systems, we specialise in providing fully engineered turnkey systems—handling every stage of your project from initial design through to final commissioning. Our complete solutions are tailored to your process, ensuring optimal performance, compliance, and ease of operation across a wide range of industries.

What Is a Turnkey System?

A turnkey system is a fully managed solution where we take care of everything:

- System design & engineering

- Equipment sourcing & fabrication

- Control integration & software • Full mechanical and electrical installation

- Commissioning, testing, and staff training

From concept to completion, you benefit from a single point of contact, guaranteed compatibility, and streamlined project delivery—backed by decades of experience in pneumatic conveying, vacuum systems, and bulk material handling.

Our Turnkey Process

Consultation & Design

- Inspection and certification support

- Replacement of expired or damaged explosion panels

- ATEX/DSEAR-compliant installations for confined process equipment

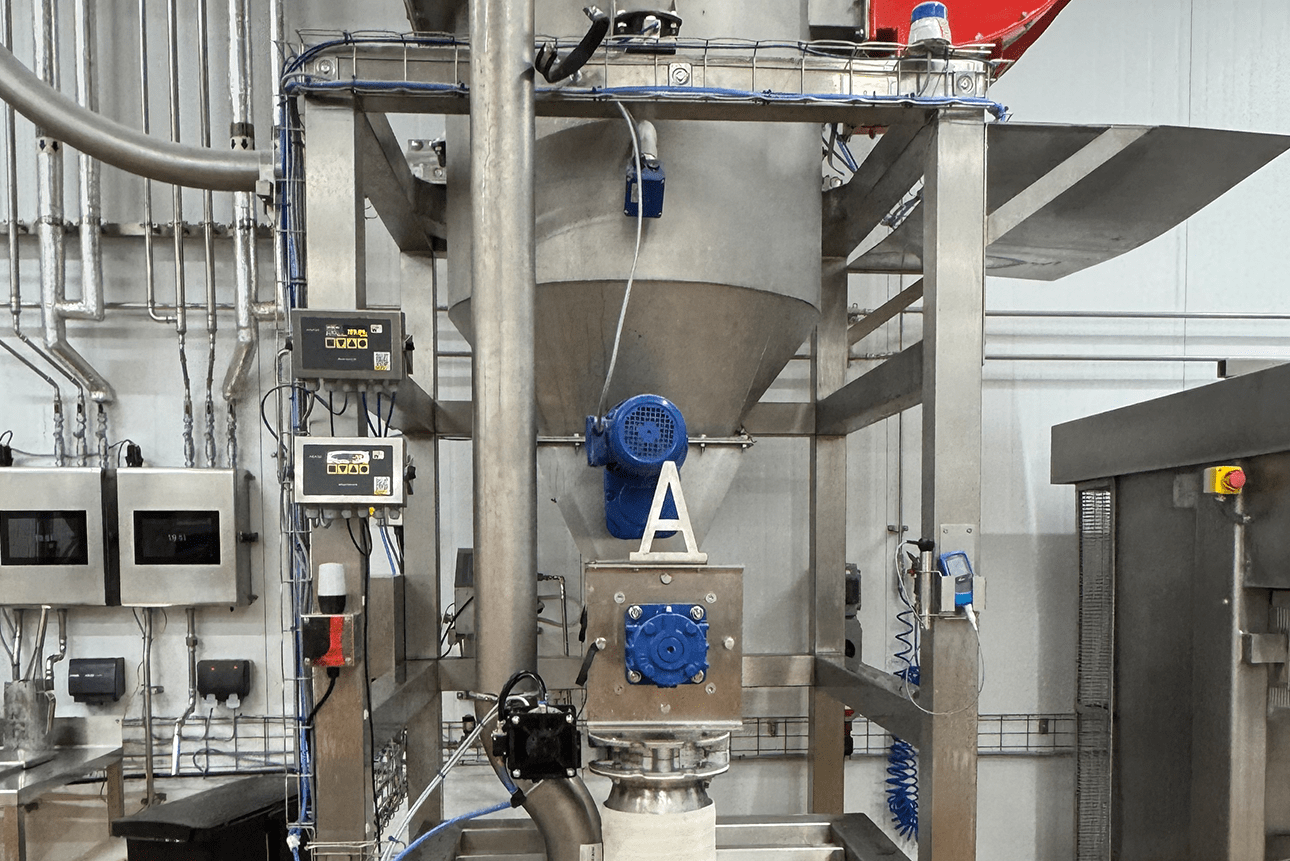

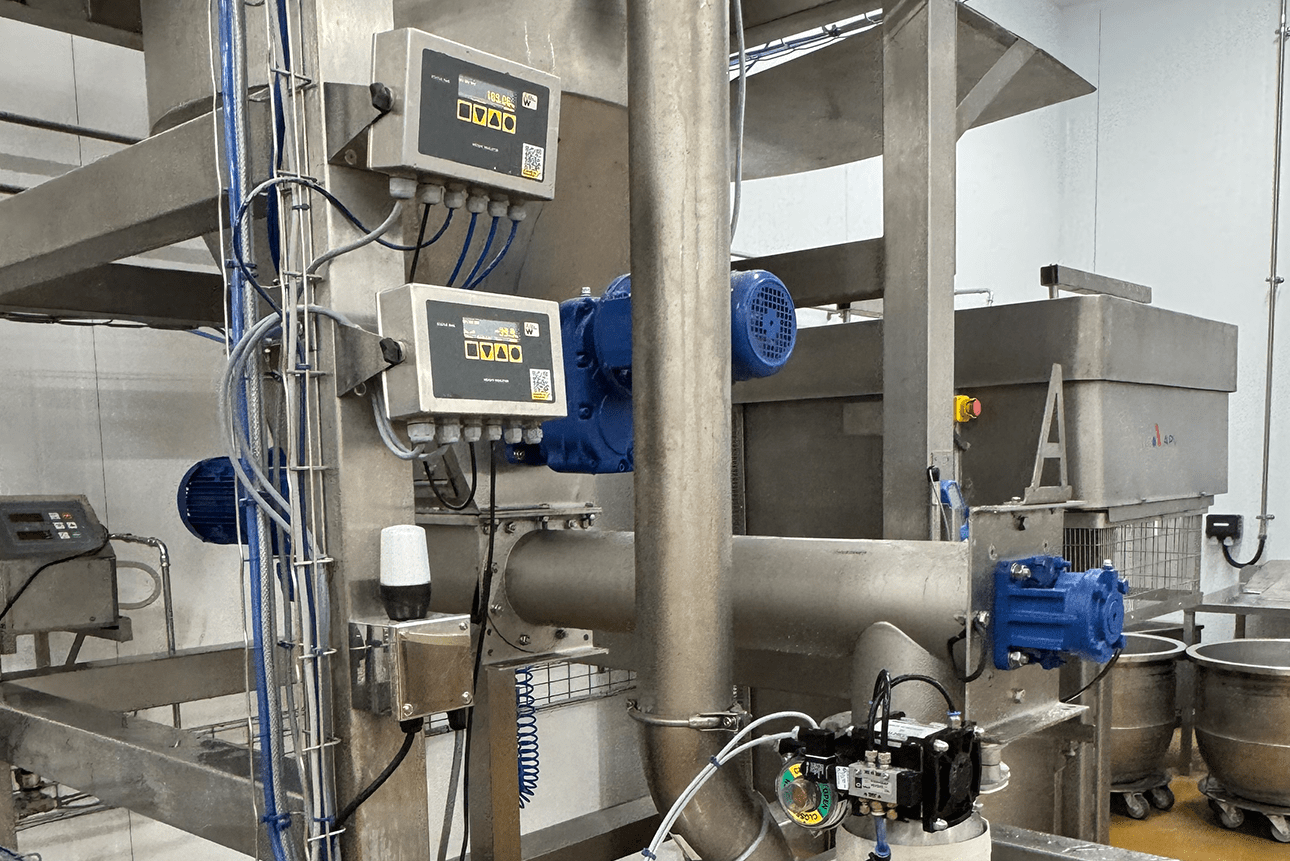

Component Supply & Fabrication

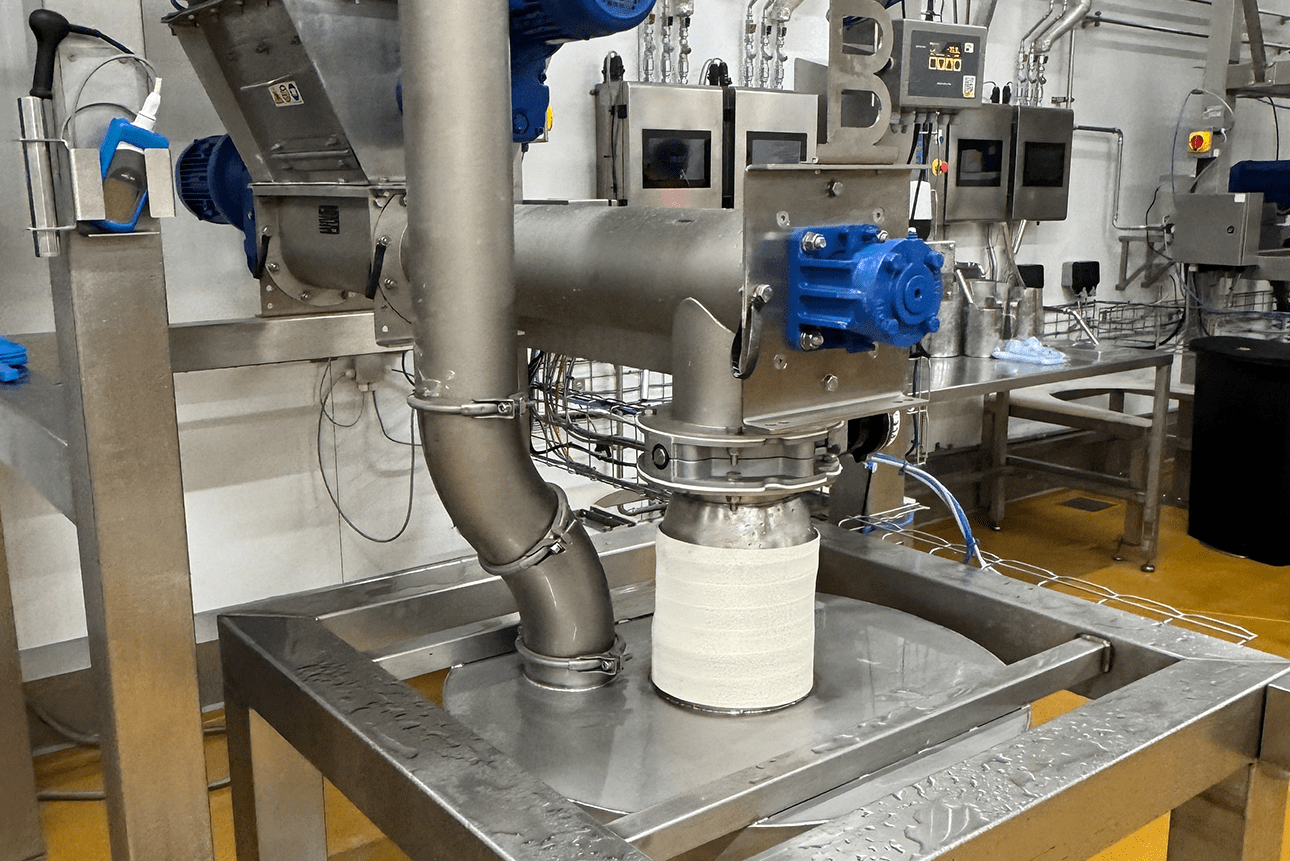

- We supply and integrate high-quality equipment—including blowers, rotary valves, diverters, filters, cyclones, silos and pipework.

- ATEX-rated components are specified where required.

Installation & Commissioning

- Our experienced engineers or approved contractors handle complete on-site installation.

- All systems are fully tested, validated and commissioned to spec.

Training & Aftercare

- We provide operator training, manuals and long-term service plans.

- Optional maintenance contracts ensure continued uptime and reliability.

Systems We Deliver

We design and install turnkey systems across a variety of applications, including:

- Central Vacuum Cleaning Systems

Pneumatic Conveying (Pressure & Vacuum) - Bulk Bag Unloading / Big Bag Systems

- Dust Collection & Filtration Units

- Silo Handling & Transfer Systems

- Waste Transfer Systems

- Ingredient Handling for Food & Feed

- Recycling & Waste Processing Lines

All systems are tailored to suit your site, material characteristics, flow rates and hygiene or regulatory requirements (including ATEX and HACCP compliance).

Industries We Serve

Our turnkey solutions are trusted by companies across:

- Food and beverage production

- Pet food and animal feed manufacturing

- Plastics, resins and polymers

- Agriculture and grain storage

- Woodworking and joinery

- Foundry and mineral processing

- Packaging and logistics

If your industry involves dusty, granular, fibrous or free-flowing material, we have the expertise to automate and streamline your material movement.

Why Choose VAK for Turnkey Projects?

- Decades of Industry Experience

- In-House Design and Engineering

- Full Regulatory Compliance (ATEX, COSHH, etc.)

- No Hidden Contractors – Single Point of Responsibility

- Efficient Project Management from concept to completion

- UK-Wide Coverage with trusted aftersales support

Whether you need a new system from scratch or an upgrade of existing infrastructure, we’ll deliver a solution that’s engineered to perform—and built to last.

Ready to Start a Turnkey Project?

Let’s talk about your requirements.